- Details

- Successes

Company Growth Case Studies

Acquisition Case Studies

| Cross-Border Integration Irritants: You Change First |

| Maximizing the Value Post Acquisition |

| How Do You Combine All the Products? |

Getting Ready for Sale Case Studies

| Itâs Time to Sell |

| Lame Duck or Worthwhile Investment? |

| If we want $8 million for our company when we sell it, what do we have to do now to get that price? |

Difficult People & Situations Case Studies

| The Boss Blames Others |

| We Canât Fire Him, We Need Him |

| Itâs Not My Problem, Heâs the Problem! |

Software Case Studies

| How Do You Manage a Gorilla for a Partner? |

| Breathing New Life into a Commodity ERP System |

| How to Develop a Market Niche |

Manufacturing Case Studies

| Greening a New Product in an Old Line Business |

| Can Commodity Product Producer Differentiate for Better Profitability? |

| A 90 year old manufacturer is purchased and downsized is there a future |

- Details

- Services

âSpirit West is brilliant at facilitating a fun and painless way to get great minds to work together without us competing for air time.â

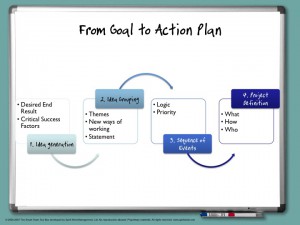

Youâve set some ambitious goals for your department or the entire company. You are just not sure how to re-organize your business, your people, roles, responsibilities and information flow to make sure your company is wired for speed and performance.

You need a solution that uses your teamâs best ideas and fast-tracks them into a plan that allows everyone to buy in. Resistance, information withholding, too many competing priorities, endless debates that donât result in decisive action and âto-doâ list overload are what blocks change.

Use this process for:

- Integrating new hires onto your existing team so that everyone knows each otherâs strengths and accept their own and othersâ challenges.

- Building solutions for complex or chronic problems.

- Uncovering what worked and what didnât, why and what to do next to learn from a project that went well, or had a few hiccups along the way.

- Product development, product maturity maps, customer service integration.

- Organizational structure changes.

- Growth strategies for lead generation, marketing plans, sales meetings, corporate strategy.

- Cross-Departmental process improvement.

- Vision, mission, critical success factors, goals and action plans.

- Re-organization of departments, companies, systems to allow for scaling up.

- Find and Embed Company Secret Sauce by identifying what makes customers come back for more and what sends them away.

Our methods, based on Disneyâs Compression Planning System for strategic planning and facilitation, allow your team to work in a collaborative way that frees everyone from these growth blockers.

As we are business growth and organizational change expertstoo, we facilitate in a way that provides insight into the problem you are trying to solve. We add value to every meeting, helping you to see what might work, what might get in the way and pointing out impacts you might not have been aware of.

You will have a clear desired end result. Understand the critical success factors to get there. Know the impacts of the decisions before you make them. Learn the methods to turn decisions into organizational projects and fit them into a logical priority list in a way that minimizes overload. Help everyone work to their strengths.

How we get started:

1. Letâs talk about what you want to be able to do after this strategic planning event that you canât do now. What works and what doesnât with your team when you get together for meetings. Time frame: 1-2 hour meeting with key stakeholders.

2. Event Design and proposal. We refine it until you approve it.

3. Event facilitation. Time frame: It depends on the team, the topic and the venue. Generally it takes 4-16 hours of concentrated focus for a team to frame the problem correctly, brainstorm solutions, narrow down into options, and select the best. Depending on the solution, it may take another 8-16 hours to turn that option into a project with actions, responsibilities, roles and dates.

4. Post-event project development: so the plan can be executed without overwhelming already taxed schedules. Time frame: It depends on how well the team understands organizational change and can integrate managing a project into their full time responsibilities. We are often engaged to manage the project for the team while they perform some of the roles.

Letâs talk about how to get your re-organization plan started. Call 604-306-7707 or

- Details

- Services

Articles:

- Why Youâre Failing to Engage Customers by Tom Rieger & Craig Kamins From: The Gallup Management Journal

- Post Merger Integration â 14 Warning Signals All Executives Should Watch For by Lorraine Rieger, Copyright 2005 All Rights Reserved

Resources:

- Association for Corporate Growth Where to find investment bankers, growth capital, service advisors to sell your company, get legal advice on a transaction or meet lenders who can provide

EndeavorIQ â unleashing your financial potential. Video based learning on strategies to increase profitability.

- What is your business worth ? Use this calculator from Money and Fortune Magazine to determine your companyâs possible value. Whatâs a multiple ? Read up on the basics of valuation.

- How to Think About Succession Planning Succession planning is something every business owner must face at some point in the life cycle of their business. Itâs a process that can be complex and one that all too many business owners tend to put off until itâs imminent.

Podcast #1: Why Donât My People Manage ?

Click to play

Podcast #2: Want to Grow Your Company ? Learn How to Build High Powered Management Teams

Click to play

Podcast #3: Iâve Got a Board But itâs Become Frustrating to Manage. Now What ?

Click to play

- Details

- Services

âI was tired of doing all the big picture thinking myself. My staff didnât know how to look out for the business the way an entrepreneur does. Now they do. My job is so much easier.â

Our coaches have the tools and the in depth awareness to spot whatâs blocking your leadership and managersâ performance. We can demystify whatâs causing pain, why and show you how to change your game to get traction, even with the toughest personalities and the thorniest issues.

Yes, hearing the tough stuff doesnât feel good in the beginning. But when you start to see change around you almost immediately, the pain is soon forgotten.

Hereâs what we offer as part of our coaching programs.

- Assessments â Itâs time to really understand what each of your team members strength actually is and then to learn how to work with the innate talent and strengths you have on your team. Stop putting square pegs in round holes and expecting more.

- One-on-One Coaching â Learn to work to strengths and minimize blind spots.

- Team Coaching â Work on the process of being a team while working on the issues and decisions the business needs to address.

- High Performance â Attend to the way people work together to resolve differences once and for all. People Power Profit only when they can talk about the stuff that gets in the way of productivity, performance and profitability.

Dealing with Difficult People: Ever run into these situations?

- You know there is something more you can do for your clientâŠ.but how do you introduce it? You donât want to be pushy, or stick your nose in, or jeopardize your relationship and risk losing the clientâŠ.and yetâŠ.

- You notice the strong personalities work to their agenda which may or may not be in alignment for what the company really needs. They are great at their job but also difficult to manage. And having an affect on others you donât like. What should you really be saying?

- At meetings, your team gives updates, but not insights. New ideas are shot down fast so no one ventures anything new or innovative. You donât want to settle for that status quo. Learn how to break through the pattern by making it ok to make suggestions by changing how you run your meetings.

- You want a decision, but the discussion goes round and round. Everyone gives their ideas and yet hours go by and there never seems to be any consensus. Productivity is paralyzed. You need your team to learn to call a âtrial closeâ.

- Your business partner loves to do things a certain way. And it grates on your nerves. The impacts of his or her actions reverberate through the business. How do you get your partner to see the effects and make changes? It starts with changing what you are willing to discuss with your partner⊠and getting the help to say it so you are heard effectively.

If youâve had any of these thoughts or are dealing with frustrating people, there is something you donât know about the art of initiating the difficult conversation. The key is âDonât make it about you.â If youâre not sure what that means or how that works, and know itâs easier said than done, you want to talk to Rob. As a hospital chaplain, consultant, mediator, negotiator and as an executive coach he has had many years of experience in initiating the difficult conversation. Call 604-377-4307.

If youâre reading this, youâre ready to stop waiting for better performance and start making it happen. If youâre ready to make changes in the way you are leading and managing because you keep getting results you donât like, then its time for a change.

If youâre reading this, youâre ready to stop waiting for better performance and start making it happen. If youâre ready to make changes in the way you are leading and managing because you keep getting results you donât like, then its time for a change.

Bringing on experts to help you get there is the right next step. Take a page from the elite athletes of the world. If you want a return on the people you have hired, the right coach gets you and them to minimize blind spots and keep the eye on the prize.

Getting that independent perspective can unlock years of frustration to get everyone back on the fast track.

Learn about what CEOs have to say about the impact of having a Spirit West coach. Read more here.

Are you ready for higher ROI?

Tell us whatâs important to you this year.